- Home

- ERPE Research Challenges

- Manufacturing and Materials

Manufacturing and Materials

ERPE research in Manufacturing and Materials (M&M) provides solutions for global challenges in industries to benefit the UK economy and society at large. The Partnership's expanding world leadership in advanced materials, synthetic biology, flow systems, medical devices and low CO2 has created applications to acquire a greater understanding of material design and manufacturing processes which cover a wide range of sectors. ERPE M&M research is crucial for renewable energy converters, structural engineering, separation technology and biomedical devices.

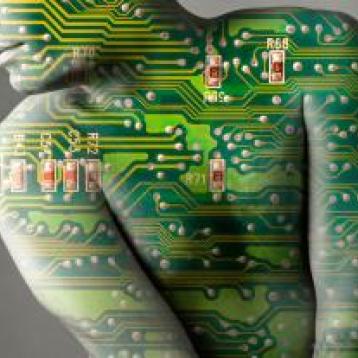

The ERPE M&M research focuses on synthesis and studies of properties of advanced materials as well as processes used in sustainable engineering and surface imaging. Using 32 various domains of modelling, computational physics, analysis, human factors, digital engineering, visualisation and robotics has offered opportunities for internal and external cross-disciplinary collaborations across product life-cycles. The materials and structures research also encompasses the development of novel materials and their integration with electronics for creation of smart sensors and systems.

ERPE M&M research focuses on Composite Materials, Polymers, Inorganic Materials, Nanomaterials and Advianced Materials Synthesis. Substantial research effort is centred on the materials for applications in Snow and Ice conditions as well as at the extremes of thermodynamic parameters such as temperature, pressure, magnetic and electric fields. ERPE M&M forms an essential part of the Centre for Science at Extreme Conditions through the programme of materials synthesis as well as the design and engineering of instruments for high-pressure applications and sample environment for lab-based research and research at the central neutron and synchrotron facilities. .

Bio-Medical/Healthcare Technology

The EPRE (M&M) has outstanding expertise in micromechanics, tissue engineering, computational mechanics, micro/nanomanufacturing, thermo-fluid mechanics and digital design and manufacture to address biomedical engineering challenges, including cancer diagnostics and tissue engineering. A novel diagnostic microscale resolution tool: from structural health monitoring to tissue quality prediction, and sensing for prostate cancer diagnostics.

Multiscale Fluid Mechanics

EPRE (M&M) uses experimental modelling of fluid and thermal processes and the knowledge of complex mixtures of liquids, solids, and gases to deliver innovation in sustainable materials and energy production. The Partnership's research into crystallisation, chemical looping, and CO2 capture enables the development of techniques for manufacturing novel chemical products and for enhancing combustion of fuel and efficient separation of CO2. New modelling techniques for fluids are developed and applied to various challenging problems such as adapting and developing entirely new laser diagnostic techniques for sprays and chemically reacting flows undergoing heat transfer. EPRE (M&M) is developing new work on urban pedestrian/traffic dynamics computational research in Micro and Nanofluid Dynamic.

Reaction Engineering and Catalysis

EPRE (M&M) aims to contribute to today's world challenges providing real solutions in the current energy production and emission control scenarios.

The partnership drives the programme of close collaboration with the industry to identify and overcome real problems in an innovative way. The Partnership's priority is to develop an early-stage technology that can be taken to a level where commercialisation becomes an economically viable option. To pursue this research approach, we have a stimulating working environment within the recently opened £350K Catalysis Design Laboratory, equipped with the state of the art facilities for synthesis, reaction testing and characterisation.

Systems Modelling: from Atoms to Processes

EPRE (M&M) research combines fundamental physical understanding with advanced numerical methods to design better products and processes. Key to this research are techniques for modelling at each appropriate scale, and for scale-bridging so that the properties of systems at different scales can be linked, optimised and controlled.

High-Performance Computing, Digital and Smart Engineering

EPRE (M&M) internal and external cross disciplinary collaborations have worked intensively on the integration of novel materials and devices with electronics to sense a range of physical properties such as heat, light, sound, radiation or chemical signatures such as pathogens or gases across for products and their life cycle. Using modelling, computational physics, analysis, human factors, digital engineering, visualisation and robotics has provided opportunities over the complete spectrum from design through to fabrication including the in-house capability to post-process foundry wafers to create more than Moore systems and deploy them in a broad range of applications.

ERPE M&M has a well-established cross-disciplinary programme on development of Smart Microsystems, micro and nano-scale devices that combine electronic integrated circuits with additional, non-electronic components on a single substrate, thereby providing additional functionality. Such microsystems can be sub-divided into a myriad of application groups, including chemical, biological, optical, mechanical, electromagnetic and fluidic.

The Partnership develops a range of energy critical applications such as the next generation smart phones, wearable devices, as well as other type of smart, embedded, wireless devices that make up future internet of things networks.

The ERPE is dedicated to researching solutions that respond to the climate emergency.

The ERPE is committed to the vision that Edinburgh should be the data capital of Europe. With the breadth of knowledge across the ERPE, this target is achievable.

ERPE has been at the forefront of various transport research.

Read about PROTEUS, IMPACT, 4MD, SONOPILL and more ground breaking healthcare research

Read about how our researchers are helping to shape government decisions.